Warehouse Design & Layout Consulting by Warehouse1

Maximize Storage. Increase Efficiency. Scale with Confidence.

Maximize Storage. Increase Efficiency. Scale with Confidence.

At Warehouse1, we design intelligent, high-performance warehouse layouts that help you optimize every square foot, improve material handling, and reduce labor costs. Whether launching a new facility or optimizing an existing one, we deliver tailored solutions aligned with your operational goals and future growth.

Warehouse1 Provides End-to-End Warehouse Layout Solutions

Warehouse1 is more than just a provider of storage and material handling systems—we’re your strategic partner in warehouse optimization. With 35+ years of industry-leading experience, our Material Handling Consultants and Staff Engineers bring a deep understanding of facility design, space planning, and workflow efficiency.

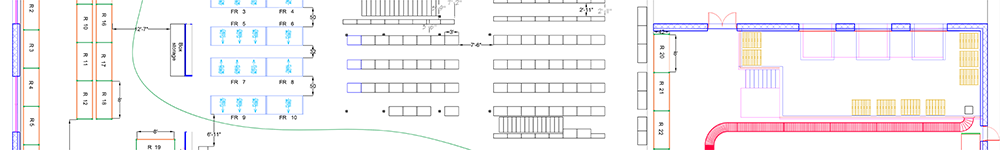

- Custom Warehouse Layout Design: CAD-based designs tailored for density, speed, or flexibility.

- Certified CAD Drawings & 3D Models: Visualize your new layout with professional 2D and 3D renderings.

- Engineer-Stamped Drawings & Permitting: We ensure compliance and secure permits with sealed drawings.

- Process Flow & Slotting Optimization: We study your operations to reduce travel time and improve throughput.

- Racking & Storage System Integration: From VLMs and ASRS to pick modules and mezzanines, we plan and install the right solution for your project.

How We Engineer Efficiency

We apply data-driven design to create safe, scalable, and compliant facilities. Every project includes:

| Focus Area | Key Objective |

|---|---|

| Inbound & Outbound Workflows | Reduce dock-to-stock touchpoints |

| SKU Velocity Mapping | Match storage to product movement |

| Labor Optimization | Reduce travel, improve ergonomics |

| Peak Demand Design | Support seasonal surges |

| Safety & Code Compliance | Meeting OSHA, IBC, & local fire codes |

| Future Growth Projections | Built-in expansion zones |

Trusted Across Industries for 35+ Years

We’ve helped hundreds of organizations transform their warehouse operations, from Ecommerce and 3PL to government, food and beverage, and manufacturing.

We’ve helped hundreds of organizations transform their warehouse operations, from Ecommerce and 3PL to government, food and beverage, and manufacturing.

Industries We Serve:

- Ecommerce & Order Fulfillment

- Food & Beverage Distribution

- Automotive & Heavy Equipment Warehousing

- Cold Storage & Temperature-Controlled Facilities

- Manufacturing & Assembly Plants

- Government, Military, & Municipal Warehouses

Integrated Systems We Support

The right storage systems and material flow strategies make all the difference. We specialize in:

The right storage systems and material flow strategies make all the difference. We specialize in:

- Pallet Racking (Selective, Pushback, Drive-In, Cantilever)

- Gravity Flow Racks & Pick Modules

- Modula VLMs (Vertical Lift Modules)

- AS/RS & AMR Solutions

- Conveyor & Sortation Systems

- Mezzanines & Modular Offices

All are designed with safety, durability, and growth in mind!

With Warehouse1, you can have confidence that your storage solutions are safe, compliant, and built to last.

Why Choose Warehouse1?

- ✔️ 35+ Years of Industry Experience

- ✔️ In-House Engineers and CAD Team

- ✔️ Compliance-First Design Philosophy

- ✔️ Warehouse Efficiency Recommendations

- ✔️ Full-Service Project Management

Let’s Design Your Next Warehouse

Whether you need an audit, a layout redesign, or a ground-up plan, our team is ready!

Book Your Free Warehouse Assessment Today

Call us at 888-558-1830

Email [email protected]

Contact Warehouse1 today to get started.