Maximize Efficiency with Warehouse Pallet Racking Systems

In today’s fast-paced warehouse operations, maximizing every square foot is essential to staying competitive. Pallet racking systems are the foundation of any efficient warehouse, enabling businesses to optimize their storage space and streamline operations. In this guide, you’ll learn how to select the right racking systems, maximize storage efficiency, and explore cost-saving options, including used pallet racks.

Understanding Your Warehouse Needs: The First Step to Efficiency

Before selecting pallet racking systems, it’s important to understand the specific requirements of your warehouse. Asking the right questions upfront can save time, money, and ensure a tailored solution that meets your unique needs.

Key Considerations for Warehouse Efficiency

Product Characteristics: What types of products will you be storing? Consider the weight, size, and fragility of the material.

Product Characteristics: What types of products will you be storing? Consider the weight, size, and fragility of the material.- Inventory Volume: How much inventory needs to be stored, and how will it fluctuate?

- Warehouse Layout: What is the usable floor space and ceiling height? How do pallet racks fit into existing walkways and traffic flow?

- Accessibility Needs: Will you need frequent access to certain products? If so, lower rack levels may be ideal for high-demand items.

Warehouse Pallet Racking 101: Common Types and Applications

Understanding the different pallet racking systems available is essential to making the right decision for your warehouse. Here are the most common racking types and their applications:

Selective Pallet Racks

Selective Pallet Racks

- Description: The most commonly used racking system, selective rack is known for quick and easy forklift access to pallets.

- Ideal For: Warehouses that require flexible storage and frequent loading/unloading.

Drive-In Pallet Racks

Drive-In Pallet Racks

- Description: Designed for high-density storage, drive-in racks allow forklifts to enter lanes with last-in, first-out (LIFO) inventory rotation.

- Ideal For: Warehouses with limited space and slow-moving inventory.

Push-Back Pallet Racks

Push-Back Pallet Racks

- Description: Similar to drive-in racks, but equipped with a gravity-fed cart system, pushback racks use a last-in, first-out (LIFO) inventory flow.

- Ideal For: Storing large quantities of similar items that need organized, rotating stock.

Pallet Flow Pallet Racks

Pallet Flow Pallet Racks

- Description: Pallet flow racks use rollers or wheels to move pallets forward as others are removed, ensuring first-in, first-out (FIFO) product rotation.

- Ideal For: Environments with high turnover where efficient inventory rotation is essential.

Gravity Flow Racks

Gravity Flow Racks

- Description: Gravity-fed roller rack systems allow for easy picking of individual items, perfect for pick-pack lines.

- Ideal For: Warehouses with high pick rates, such as eCommerce or retail fulfillment centers.

Pallet Racking with Mezzanines

Description: Combining pallet racks with mezzanine floors to maximize vertical space by creating additional storage or office areas.

Description: Combining pallet racks with mezzanine floors to maximize vertical space by creating additional storage or office areas.- Ideal For: Warehouses looking to expand storage without increasing their building footprint.

Choosing the Right Rack for the Job: Key Considerations

Once you know the common types of racking systems, it’s time to select the best option for your warehouse. Here are some critical factors to consider:

Weight Capacity

Weight Capacity

Ensure that the racking system you choose can safely support the weight of your inventory.

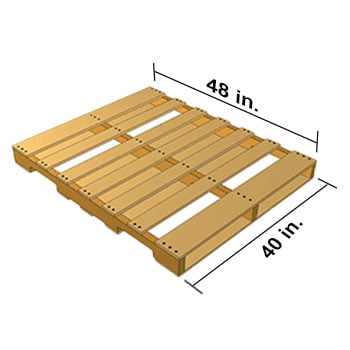

Pallet Size and Dimensions

Standard GMA pallets are typically 48" x 40", but if your warehouse uses Euro or custom-sized pallets, the rack dimensions should accommodate these.

Seismic Activity

If your warehouse is in an earthquake-prone area, special seismic-rated pallet racking may be required. Warehouse1 can help identify what’s necessary based on your region.

Optimizing Your Warehouse Layout for Maximum Efficiency

Once you’ve chosen the right pallet racks, it’s essential to optimize your warehouse layout. This ensures you get the most from your racking system while improving workflow and safety.

Maximize Vertical Space

Maximize Vertical Space

Install high-bay pallet racks to take advantage of the full height of your warehouse, especially if you have a high ceiling.

Plan for Future Growth

Consider how your warehousing needs will evolve. Choose a racking system that can be easily expanded as your business grows.

Prioritize Safety

Clearly mark aisles and weight capacities, and train forklift operators to safely navigate the racking system.

Cost-Effective Solutions: New and Used Pallet Racks from Warehouse1

New and Used Options

At Warehouse1, we understand that budget is a major concern for many businesses. We offer both new and high-quality used pallet racks to meet your needs. Our used pallet racks can save you up to 50% compared to new ones, without sacrificing safety or durability.

At Warehouse1, we understand that budget is a major concern for many businesses. We offer both new and high-quality used pallet racks to meet your needs. Our used pallet racks can save you up to 50% compared to new ones, without sacrificing safety or durability.

Rigorous Inspection Process

All used racks at Warehouse1 go through a rigorous inspection and refurbishment process to meet the same safety standards as new racks. This allows you to save money while ensuring top-tier performance and reliability.

Warehouse1: Your Partner for Pallet Racking Solutions

Whether you're looking for brand-new or high-quality used pallet racking systems, Warehouse1 has the expertise and inventory to meet your needs. We offer a full range of solutions to help your warehouse operate at peak efficiency.

Here’s What Warehouse1 Can Offer You:

- Free Consultation: Get a professional assessment of your warehouse space and personalized recommendations.

- Custom Rack Design & Installation: We design, deliver, and install the perfect racking system for your unique needs.

- Used Rack Savings: Save up to 50% with used pallet racking that meets the highest safety standards.

- Wide Selection of Racks: From selective to drive-in racks, we offer a variety of racking systems to fit your specific storage requirements.

- Leasing Options Available: We offer leasing options to ensure you can invest in the right equipment without upfront strain.

Contact Warehouse1 Today!

Don’t let inefficient storage hold back your operations. Contact Warehouse1 today to explore new and used pallet racking solutions, maximize your warehouse space, and save on costs.

Call us at 888-558-1830 to get started!